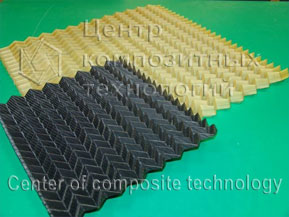

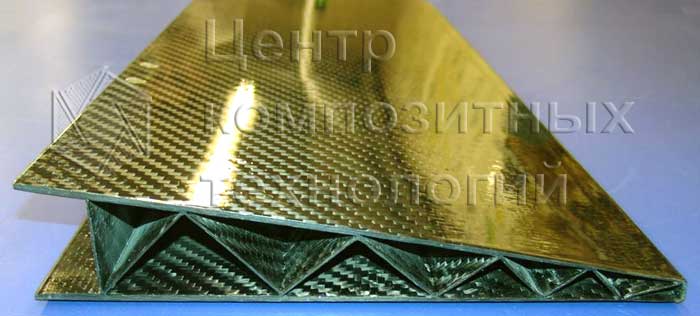

The work in the field of composite technology aiming at industrial application was initiated on Aircraft Manufacturing Department in the 80s of the XX century. At that time first claims for a discovery (1989) were made, first works (1991) were published and theses were presented by V.E. Desyatov (PhD, 1992) and V.I. Khaliulin (doctor of engineering, 1997). The topics were synthesis of folded structures and processes for these structures manufacturing from composite materials.

In 1992 first contractual works were performed for NPO Trud named after N.D. Kuznetsov (Samara). The aim was the development of folded sound-absorbent structure from polymer composite materials for NK-93 engine.

Segregation of Center of Composite Technology as a structural unit of Aircraft Manufacturing Department took place in September, 2001, when Airbus contracted Center of Composite Technology.

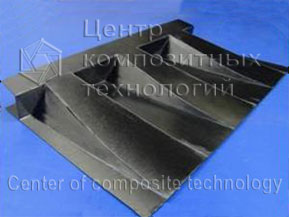

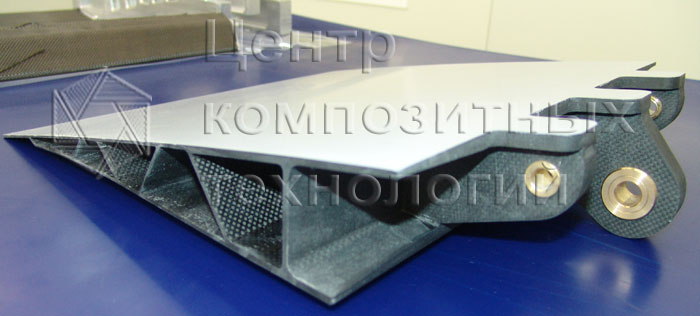

The topic of research was development of folded structures for multilayer panels of composite fuselage. The work finished in 2012. Simultaneously Center of Composite Technology was performing work for EADS and Diehl Aircabin GmbH. Topic of technology development for polymer composite folded structures manufacturing prevailed as well as experimental analysis of mechanical properties and impact resistance of panels with folded core.

In that period Center of Composite Technology was also performing work for domestic enterprise: All-Russian Institute for Aviation Materials (VIAM), Central Aerohydrodynamic Institute (TsAGI), Aviadvigatel JSC, NPO Rubin JSC, INUMIT CJSC, AeroComposit CJSC, KAMAZ JSC, Aviatar-SP CJSC, Kazan Helicopters JSC.

Center of Composite Technology has been broadening the field of research and the emphasis has been switched to transfer molding technologies (RTM, infusion, etc.).

Experience obtained in the course of work is used for bachelors, masters and specialists training as well as advanced training for faculty staff and industry employees.

Center of Composite Technology received a massive support from University development programs: Innovation and Education Program of 2007-2008 and Scientific and Research University Development Program of 2009-2018. Funding from these programs allowed equipping the Center with state-of-the-art research and processing equipment.

Application of Tailored Fiber Placement technology is often considered when the new composite structures are being developed.

At the moment Center of Composite Technology is cooperating with large domestic aerospace enterprises and industries. Among them are Scientific and Production Association Saturn, Kazan Helicopters Public Corporation, Central Aerohydrodynamic Institute, AeroComposit Ltd., etc.

Owing to active position of leadership a team of young and creative employees was formed. Research and educational activities of Center of Composite Technology are essential and harmoniously blended with the general concept of vigorous introduction of composite technology into machine engineering.