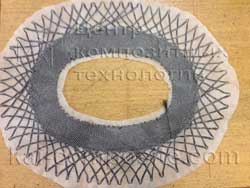

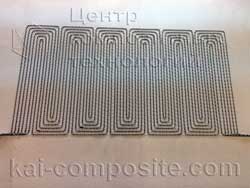

We manufacture preforms using TFP technology. This technology provides an opportunity to create tailored reinforcement of composite parts and local reinforcement areas.

Tajima TFPM

Multihead embroidery machine with fiber placement

manufacturer: Tajima GMBH

| Specification | |

|---|---|

| Number of stitching heads | 2 |

| Maximum roving fixation velocity | not less than 1000 stitches per min |

| Placement material | carbon glass aramid roving |

| Working area | 800x1000 mm |

TFP – essence of the process

Advantages of TFP

- Fiber placement along load transfer vectors.

- A possibility to create local reinforcement areas.

- Manufacturing net-shape preforms.

- High accuracy and repeatability of the process.

- Process automation.

- Optimum application of load bearing capacity of the roving (weight reduction).