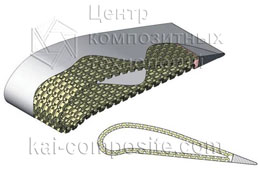

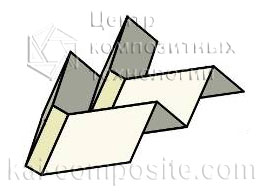

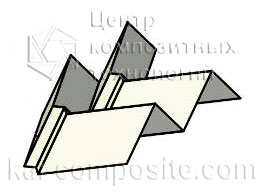

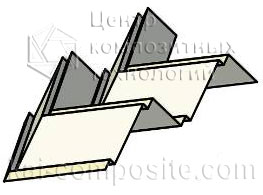

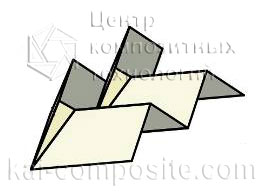

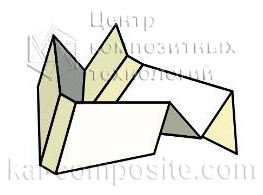

One of the most simple basic folded structures is a plane z-crimp. However, applying methods of modification it is possible to get new types of folded cores with usable properties: with cellular structure, single or double curvature, curvilinear enveloping surfaces and areas of contact for bonding to the skins, with perimeter of the part, convenient for joining with elements of carcass or joining core blocks with each other.

Basic unit of Z-crimp folded structure and its modification

|

|

|

|

|

|

|

|

|

|

|

|

An important task is to increase strength of the joint between a core and a skin. One of the solutions is development of a core with a large area of contact with the skin. For this purpose a large class of structures with such areas in enveloping surfaces was developed.

Classification of processing schemes for Z-crimp manufacturing

Features of synchronous Z-crimp manufacturing process: a part is produced from a sheet in a single setup; forming of the core is performed along the whole surface of the sheet by folding along marking lines.

Features of cyclic Z-crimp manufacturing process: gradual application of shaping to local areas of the sheet, which allows continuous manufacturing of a core from a tape or roll material. In case of serial manufacturing of single-type parts cyclic method has unquestionable advantages, such as: production of folded cores with unlimited length in the direction of crimp with a minimum amount of manual operations and high efficiency of manufacturing process.